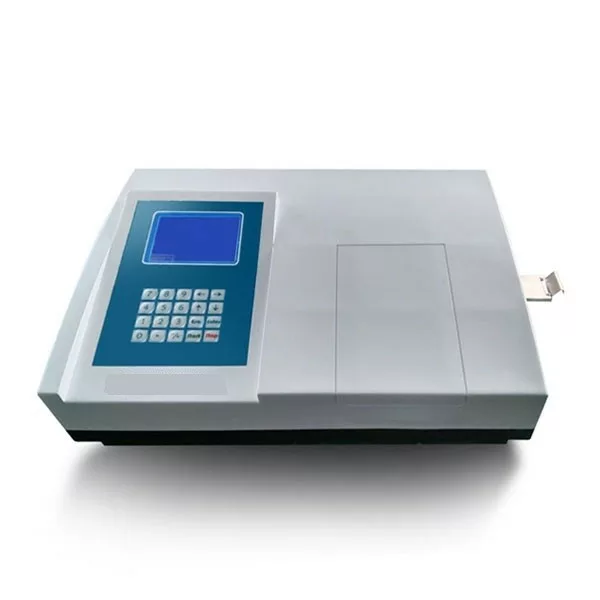

XRF Analyzer KXA/A/10: Revolutionizing Elemental Analysis with Precision and Speed

In modern laboratories and industrial settings, understanding the elemental composition of materials is critical for quality control, compliance, and research. The XRF Analyzer KXA/A/10 (X-ray Fluorescence Analyzer) is a powerful tool that enables accurate, non-destructive elemental analysis across a wide range of applications. From metal alloys to geological samples, and from environmental testing to consumer goods, the XRF Analyzer provides quick, reliable results that are essential for making informed decisions in today’s fast-paced environments.

What is an XRF Analyzer?

An XRF Analyzer is an advanced instrument that uses X-ray fluorescence to determine the elemental composition of a sample. The analyzer directs a beam of X-rays at the sample, causing the atoms within the material to emit secondary (or fluorescent) X-rays. These emitted X-rays have energies that are characteristic of specific elements, allowing the XRF Analyzer to identify and quantify the elements present in the sample.

XRF Analyzers are prized for their ability to deliver rapid, non-destructive testing with minimal sample preparation. This makes them ideal for use in the field, as well as in laboratories where speed and accuracy are paramount. These analyzers are used in a wide range of industries, including mining, metallurgy, environmental science, recycling, and manufacturing.

Key Features of XRF Analyzers

- Non-Destructive Testing: XRF Analyzers perform elemental analysis without altering or damaging the sample, preserving it for further testing or use.

- Rapid Results: XRF Analyzers provide quick results, often within seconds, making them ideal for on-the-spot decision-making in industrial and field applications.

- Broad Elemental Range: Capable of detecting a wide range of elements, from heavy metals like lead and mercury to lighter elements like sodium and magnesium, XRF Analyzers offer versatility in testing.

- High Sensitivity and Accuracy: XRF Analyzers deliver precise measurements with high sensitivity, even at trace levels, ensuring reliable data for critical applications.

- Portability: Many XRF Analyzers are designed to be portable, with handheld models that can be easily transported to field locations, enabling on-site analysis.

- User-Friendly Interface: With intuitive software and easy-to-navigate controls, XRF Analyzers are accessible to both novice and experienced users.

- Data Management and Reporting: Modern XRF Analyzers feature advanced data management capabilities, including the ability to store, export, and analyze data, ensuring comprehensive reporting and record-keeping.

- Compliance with Standards: XRF Analyzers are designed to comply with international standards and regulations, ensuring that results are consistent and recognized globally.

Benefits of Using an XRF Analyzer

- Enhanced Quality Control: XRF Analyzers enable precise monitoring of material composition, ensuring that products meet stringent quality standards and specifications.

- Cost and Time Efficiency: By providing rapid, non-destructive analysis, XRF Analyzers reduce the need for extensive sample preparation and multiple tests, saving both time and resources.

- Versatility Across Industries: XRF Analyzers are used in a wide array of industries, from mining and metallurgy to environmental testing and consumer goods manufacturing, making them an invaluable tool for diverse applications.

- Field and Laboratory Use: The portability of XRF Analyzers allows for in-field testing, while their high accuracy and sensitivity make them equally valuable in laboratory settings.

- Regulatory Compliance: For industries subject to strict environmental and safety regulations, XRF Analyzers ensure compliance by accurately detecting and quantifying hazardous elements.

- Non-Destructive Testing: Because XRF analysis does not alter the sample, it is ideal for testing valuable or limited materials where preservation is crucial.

Applications of XRF Analyzers

- Mining and Geology: In the mining industry, XRF Analyzers are used to determine the composition of ores, guiding exploration and extraction processes. Geologists also use XRF to analyze rock and soil samples for research and mapping.

- Metallurgy: XRF Analyzers are essential for identifying and verifying metal alloys, ensuring that materials meet the required standards for manufacturing and construction.

- Environmental Testing: XRF Analyzers play a critical role in detecting hazardous elements in soil, water, and air samples, helping to monitor pollution and ensure compliance with environmental regulations.

- Recycling and Waste Management: In the recycling industry, XRF Analyzers are used to sort and identify materials, particularly in the separation of valuable metals from waste.

- Consumer Goods: Manufacturers of consumer products, such as electronics and toys, use XRF Analyzers to detect the presence of restricted substances, such as lead and cadmium, ensuring product safety and compliance with international regulations.

- Archaeology and Art Conservation: XRF Analyzers are employed in the analysis of artifacts and artworks, helping conservators and researchers understand the composition and provenance of historical objects.

- Food and Agriculture: XRF Analyzers are used to assess the mineral content of agricultural products and food items, ensuring they meet nutritional and safety standards.

How to Choose the Right XRF Analyzer

When selecting an XRF Analyzer, it’s important to consider the specific needs of your application. Key factors to evaluate include the elemental range and sensitivity required, the portability of the device, and the ease of use. If your work involves field analysis, a portable, handheld XRF Analyzer may be ideal. For laboratory-based applications, consider a benchtop model with higher sensitivity and advanced data management features.

Other important considerations include the analyzer’s compliance with relevant industry standards, the software interface, and the level of support provided by the manufacturer, including training and maintenance services. It’s also essential to consider the analyzer’s ability to handle the types of samples you work with, whether they are solids, liquids, or powders.

Conclusion

The XRF Analyzer is an indispensable tool for anyone involved in elemental analysis. Whether you’re working in mining, environmental science, manufacturing, or any other field where material composition is critical, an XRF Analyzer offers the precision, speed, and reliability you need to make informed decisions. With its ability to deliver rapid, non-destructive results across a wide range of elements, the XRF Analyzer stands as a cornerstone of modern analytical techniques.

Explore our selection of XRF Analyzers to find the perfect match for your needs. With advanced features, user-friendly design, and robust data management capabilities, our XRF Analyzers will empower your laboratory or field operations, ensuring accurate and reliable elemental analysis every time.

Reviews

There are no reviews yet.