Titrator: Precision, Automation, and Reliability in Modern Chemical Analysis

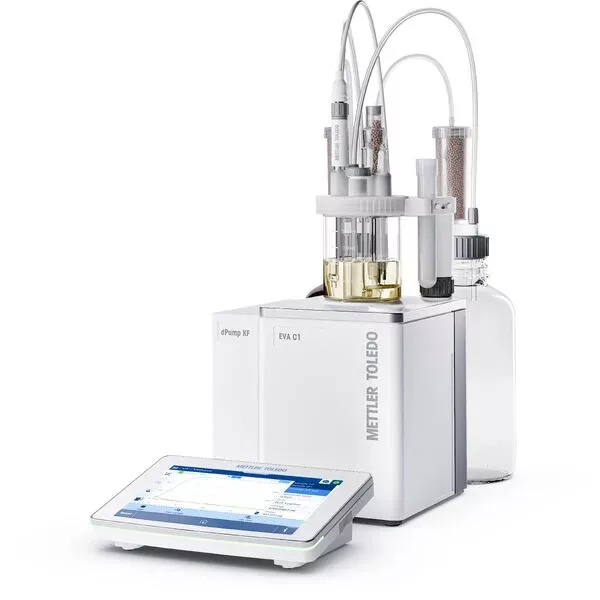

Titrator Mettler Toledo EVA C1 D is a highly specialized laboratory instrument used to perform titration—one of the most essential analytical methods for determining the concentration of an analyte in a sample. Whether in pharmaceuticals, chemical manufacturing, food and beverage quality control, or environmental testing, a titrator provides accurate, repeatable, and efficient measurements while minimizing manual effort and operator error.

In this comprehensive guide, we explore what a titrator is, its core features, applications, and the benefits it brings to laboratory environments.

What is a Titrator?

A titrator is a laboratory instrument that automates or semi-automates the process of titration by dispensing a titrant (a solution of known concentration) into a sample until the reaction reaches a defined endpoint. Using sensors such as pH, conductivity, or redox electrodes, the titrator continuously monitors changes in the solution to detect the endpoint with high accuracy.

Unlike manual titration—which relies on visual cues and operator judgment—a modern titrator uses advanced sensors and computational analysis to ensure precise, repeatable results while reducing human variability.

Key Features of a Modern Titrator

1. Automated or Semi-Automated Titrant Delivery

Titrators deliver titrant with high precision, often controlled by micro-dosing systems that respond to real-time sensor feedback. This ensures consistent endpoint detection across all sample types.

2. Support for Multiple Titration Techniques

Modern titrators can perform a wide range of titration methods, including:

-

Acid–Base Titration: Measures pH changes for acid or base concentration determination.

-

Redox Titration: Used in oxidation–reduction analyses.

-

Complexometric Titration: Ideal for determining metal ions in water, food, or industrial solutions.

-

Precipitation Titration: Suitable for halide determination and reactions forming solid precipitates.

-

Karl Fischer Titration (Coulometric or Volumetric): Used to measure moisture content with extreme accuracy.

3. Advanced Endpoint Detection

With high-precision electrodes and optical sensors, titrators ensure accurate endpoint identification even in complex or multi-step reactions.

4. Programmable Methods & Custom Protocols

Users can store predefined titration methods or create customized protocols, allowing quick setup and consistent performance across repetitive tests.

5. Data Logging, Reporting & Digital Integration

Modern titrators store key parameters such as titrant volume, sample ID, and endpoint value. Many models integrate with:

-

LIMS systems

-

USB/PC software

-

Cloud-based data platforms

This supports compliance with industry standards and simplifies audit trails.

6. Sample Automation Compatibility

Titrators can be paired with autosamplers or sample changers, enabling fully automated batch processing—ideal for busy laboratories with high throughput demands.

7. Intuitive Interface

Touchscreen displays, guided workflows, and preprogrammed methods make titrators user-friendly, even for technicians with limited experience.

Applications of Titrators

1. Pharmaceutical Industry

Used for analyzing APIs, excipients, drug formulations, and moisture content (Karl Fischer). Ensures final products meet regulatory standards for potency, purity, and stability.

2. Food & Beverage Industry

Titrators monitor parameters such as acidity, salt content, preservatives, sugar levels, and moisture—critical for taste, shelf life, and safety.

3. Chemical & Petrochemical Industry

Ideal for analyzing fuels, oils, lubricants, surfactants, and industrial chemicals. Helps maintain product specifications and quality control.

4. Environmental Monitoring

Used for testing water quality, soil chemistry, and pollution indicators including alkalinity, chloride levels, dissolved oxygen, and more.

5. Academic & Research Institutions

Supports teaching, experimental research, and advanced chemical studies requiring consistent quantitative analysis.

Benefits of Using a Titrator

1. Superior Accuracy & Reproducibility

Automated sensing and dosing systems minimize human error, ensuring consistent results across repeats.

2. Higher Laboratory Efficiency

Automation accelerates titration processes and frees personnel to focus on other analytical tasks.

3. Better Data Management

Digital documentation enhances traceability and supports regulatory compliance.

4. Reduced Operator Fatigue

Eliminates the need for constant manual monitoring, especially in labs handling large numbers of samples.

5. Versatile Across Industries

Handles an extensive range of sample types and titration methods, making it suitable for almost any laboratory setting.

How to Choose the Right Titrator

1. Titration Method Requirements

Select a titrator capable of performing your most common titration types—especially if you require Karl Fischer or complexometric titrations.

2. Sample Volume & Throughput

High-throughput labs benefit from autosamplers or multi-channel titrators.

3. Accuracy & Sensitivity

Choose models with high-precision electrodes and fine-resolution dosing systems for sensitive analyses.

4. Software Integration

Ensure compatibility with your LIMS or digital environment for seamless data transfer.

5. Ease of Use

User-friendly interfaces, preprogrammed methods, and clear workflows reduce training time and setup errors.

Conclusion

A titrator is an indispensable tool for modern laboratories requiring accurate and reliable chemical analysis. With automated endpoint detection, advanced data management, multiple titration methods, and high productivity, titrators enhance precision, reduce operator workload, and improve overall laboratory efficiency. Whether used in pharmaceuticals, food production, environmental monitoring, or academic research, a titrator ensures consistent, high-quality analytical results across diverse applications.

Reviews

There are no reviews yet.